Unifilt Corporation, a global leader in the manufacturing, distribution, removal and installation of filtering materials for potable and wastewater treatment facilities, is proud to introduce the Unifilt Air Scour. This improved solution to filter media cleaning will be on display for the first time at The American Water Works Association (AWWA) ACE14 Annual Conference and Exposition, June 8-12, 2014, at the Boston Convention and Exhibition Center. Attendees are encouraged to visit Unifilt in Booth 2573.

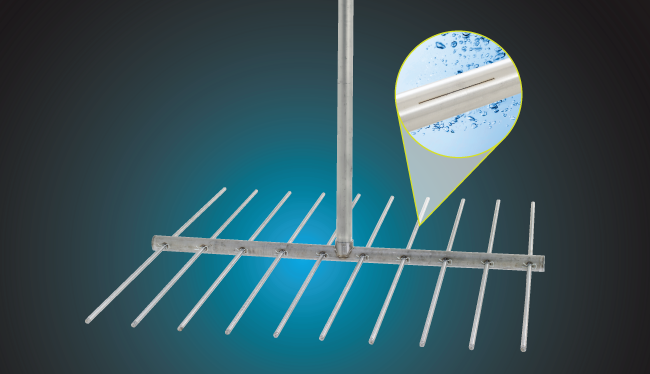

Tom Walter, Unifilt’s Chief Engineer, describes what makes the Air Scour different, “Each of the laterals features a number of our proprietary, laser-cut microslits. They resist clogging and help reduce the types of maintenance and system failures typically associated with mesh screens. For customers, this translates into increased productivity, minimized downtime and reduced labor costs.”

The user-friendly design enables fast, easy installation with no filter media removal or underdrain replacement. As the Unifilt Air Scour’s modular units simply drop down from the top and are fully supported from above, they are a cost-effective retrofit option for facilities struggling with the cost of maintaining older, outdated equipment. Made in the U.S.A. with a focus on craftsmanship and quality, each lightweight modular unit is constructed of 304 stainless steel for maximum durability.

For a limited time, qualified prospects may request an Introductory Trial of the Air Scour. Unifilt’s field installation team will set up the air grid modules, temporary piping and anchorage, connect an air supply via one of their mobile, diesel-powered blowers that features automated controls, and provide comprehensive operator training. With no permanent physical plant alterations required, it can be easily relocated or removed at any time. During the Trial period, improved plant efficiencies can be realized and quantified prior to purchase.

To discuss implementing the Unifilt Air Scour’s Introductory Trial, call 1-800-223-2882.